Labor Productivity Dashboard for a Manufacturing Company

What is a

Labor Productivity Dashboard

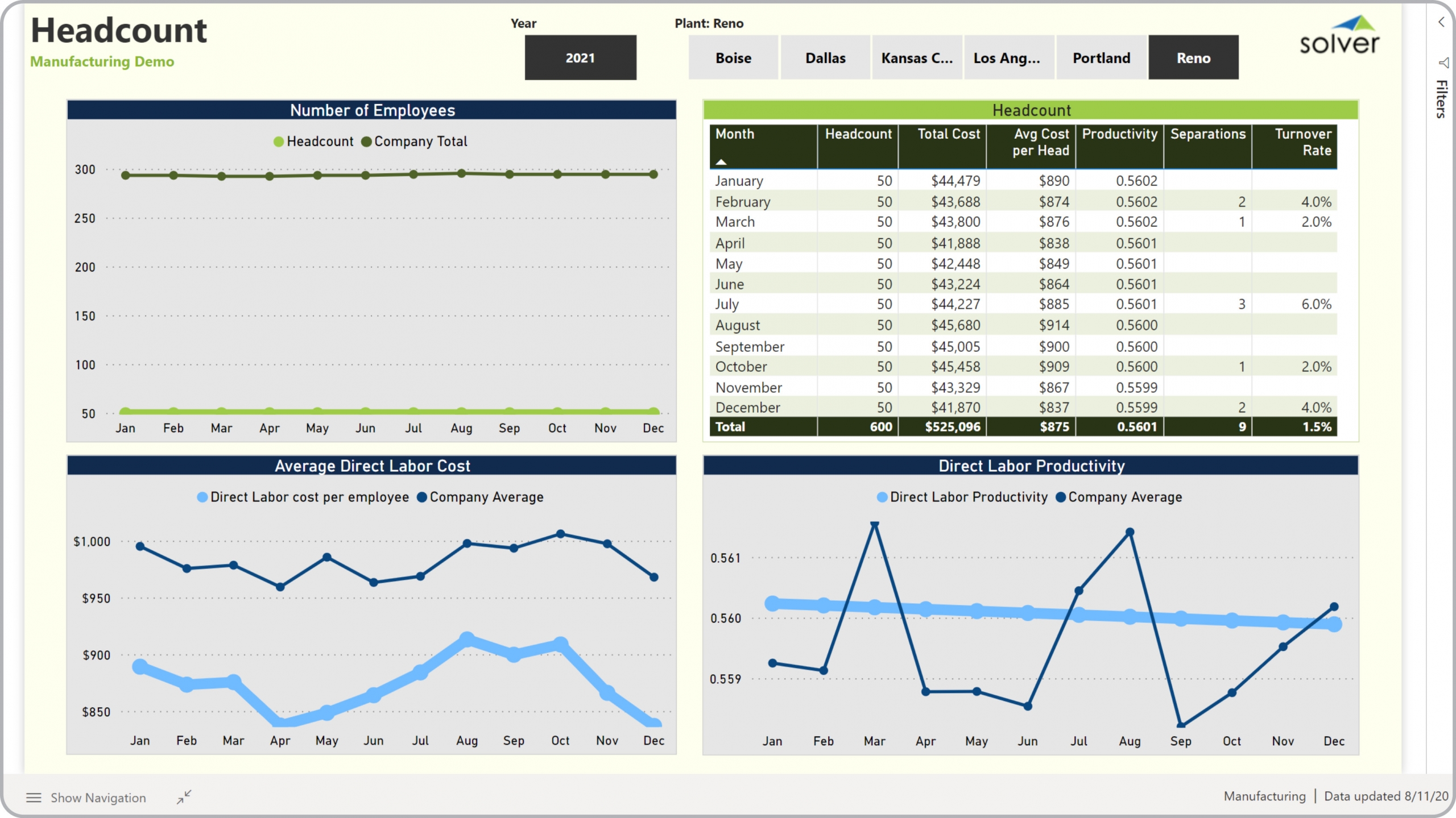

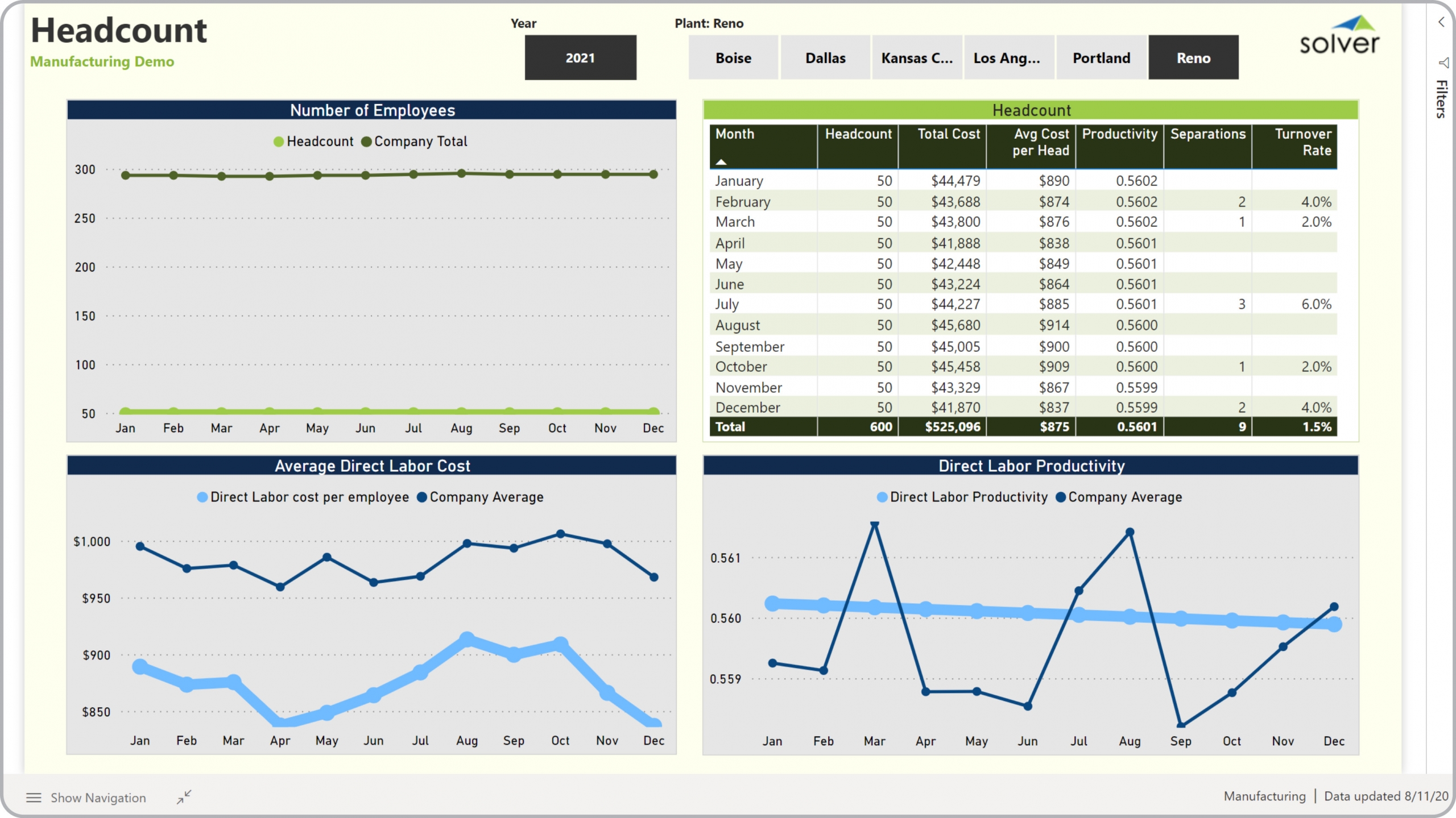

? Labor productivity dashboards are considered efficiency analysis tools and are used by Plant- and Production Managers to analyze headcount and related costs and productivity. Some of the main functionality in this type of dashboard is that it gives the user four angles of analysis, including: 1) Plant headcount and total headcount - monthly trend, 2) Average direct labor cost per employee (for the selected plant) for all plants - monthly trend, 3) Monthly metrics for headcount, total direct costs, average cost per FTE, productivity, separations, turnover rates, and 4) Direct labor productivity versus company average - monthly trend. The user can select year and plant from the top of the dashboard. You find an example of this type of dashboard below.

Purpose of

Labor Productivity Dashboards Manufacturing companies use Labor Productivity Dashboards to monitor trends in headcount, labor costs and productivity. When used as part of good business practices in Financial Planning & Analysis (FP&A), HR and operations departments, an organization can improve its revenues and margins, and it can reduce the chances that managers miss important efficiency trends or outliers.

Example of a

Labor Productivity Dashboard Here is an example of a Labor Productivity Dashboard with trends in headcount, costs and productivity. [caption id="" align="alignnone" width="2560"]

Example of a Labor Productivity Dashboard for a Manufacturing Company[/caption] You can find hundreds of additional examples

here

Who Uses This Type of

Dashboard

? The typical users of this type of dashboard are: Executives, analysts, plant managers, production managers, HR managers.

Other Reports Often Used in Conjunction with

Labor Productivity Dashboards Progressive Financial Planning & Analysis (FP&A), HR and operations departments sometimes use several different Labor Productivity Dashboards, along with efficiency reports, profitability dashboards, human capital planning, HR reports and other management and control tools.

Where Does the Data for Analysis Originate From? The Actual (historical transactions) data typically comes from enterprise resource planning (ERP) systems like: Microsoft Dynamics 365 (D365) Finance, Microsoft Dynamics 365 Business Central (D365 BC), Microsoft Dynamics AX, Microsoft Dynamics NAV, Microsoft Dynamics GP, Microsoft Dynamics SL, Sage Intacct, Sage 100, Sage 300, Sage 500, Sage X3, SAP Business One, SAP ByDesign, Acumatica, Netsuite and others. In analyses where budgets or forecasts are used, the planning data most often originates from in-house Excel spreadsheet models or from professional corporate performance management (CPM/EPM) solutions.

What Tools are Typically used for Reporting, Planning and Dashboards? Examples of business software used with the data and ERPs mentioned above are:

Example of a Labor Productivity Dashboard for a Manufacturing Company[/caption] You can find hundreds of additional examples

here

Who Uses This Type of

Dashboard

? The typical users of this type of dashboard are: Executives, analysts, plant managers, production managers, HR managers.

Other Reports Often Used in Conjunction with

Labor Productivity Dashboards Progressive Financial Planning & Analysis (FP&A), HR and operations departments sometimes use several different Labor Productivity Dashboards, along with efficiency reports, profitability dashboards, human capital planning, HR reports and other management and control tools.

Where Does the Data for Analysis Originate From? The Actual (historical transactions) data typically comes from enterprise resource planning (ERP) systems like: Microsoft Dynamics 365 (D365) Finance, Microsoft Dynamics 365 Business Central (D365 BC), Microsoft Dynamics AX, Microsoft Dynamics NAV, Microsoft Dynamics GP, Microsoft Dynamics SL, Sage Intacct, Sage 100, Sage 300, Sage 500, Sage X3, SAP Business One, SAP ByDesign, Acumatica, Netsuite and others. In analyses where budgets or forecasts are used, the planning data most often originates from in-house Excel spreadsheet models or from professional corporate performance management (CPM/EPM) solutions.

What Tools are Typically used for Reporting, Planning and Dashboards? Examples of business software used with the data and ERPs mentioned above are:

- Native ERP report writers and query tools

- Spreadsheets (for example Microsoft Excel)

- Corporate Performance Management (CPM) tools (for example Solver)

- Dashboards (for example Microsoft Power BI and Tableau)

Corporate Performance Management (CPM) Cloud Solutions and More Examples

Learn More About Solver CPM For Manufacturing

April 2, 2021

TAGS:

Reporting,

Solver,

plant,

report writer,

Microsoft,

manufacturing,

template,

staff,

practice,

Acumatica,

visualization,

Netsuite,

Finance,

planning,

GP,

dashboard,

Business Central,

excel,

ax,

forecast,

Budget,

Dynamics 365,

analysis,

budgeting,

labor,

headcount,

Cloud,

Software,

Tableau,

SAP,

example,

best,

Sage,

BC,

D365,

NAV,

Intacct,

facility,

CPM,

report,

SL,

Management,

dynamics,

Power BI,

Productivity,

labor cost,

headcount dashboard,

personnel dashboard,

productivity dashboard