High-Impact Ideas

All Examples

Recent Posts

How to Create a Successful Demand Plan

At the core of every business strategy for products and services is to provide optimal management of the supply chain. A leak or inefficiency in the supply chain eats away at the organization's bottom line. Supply chains are becoming more complex with more variations in products, distribution channels, and material planning. Accurate supply and demand planning is essential for optimal productivity and profitability.

How does a business obtain an optimal supply chain? It comes down to how well an organization can develop a demand plan. Demand is never linear and rarely easy to predict. A planning team needs to have the right historical data that can be used to create a statistical forecast, achieve consensus from the stakeholders, and be quick to pivot on changing internal or external market trends. In this article, we seek to define and discuss the elements of demand planning, analyze the cost of failure, and outline the steps to success.

What is Demand Planning?

Demand planning is a multi-step process to forecast demand, improve the accuracy of forecasts, and align inventory with peaks and troughs of demand. In other words, demand planning is the process of forecasting demand for a product or service. Successful demand planning is defined as having the right balance of inventory levels to meet customer needs while minimizing inventory surplus or deficiency. Here are the four crucial aspects of demand planning in order of importance:- Product Portfolio Management - Product portfolio management oversees the entire product lifecycle. It starts with the introduction of a new product to the eventual end of its product life cycle. Upkeep and maintenance of product data is key to statistical forecasting.

- Statistical Forecasting – Build a forecast with past inventory data, sales data, and appropriate product history to predict future data or trends.

- Trends (Internal and External) – Build into your forecast an estimate of casual influences from internal and external trends. Internal trends include the seasonality of your products and hiring talent to scale. External trends include unexpected economic crisis, competition, socio-cultural, legal, and political forces.

- Events and Promotions – Once a forecast is generated with the above factors in mind, events and promos can be used to help hit your S&OP targets.

Importance of Automated Demand Planning

Failure to adopt an automated statistical forecasting and demand planning approach can lead to a wide range of issues such as missed deadlines, unhappy customers, Inventory surplus or deficiency or delayed response to market dynamics. Delayed response means your business can lose a competitive edge or fall behind competitors. Inability to act quickly on supply chain disruptions has a material impact on both top-line and bottom-line numbers and you can end up losing market share to competitors. Below is a list of some of the business impacts of not utilizing automated planning strategies:Lost credibility

Losing credibility means losing business. Inability to fulfill customer orders due to bad inventory planning will lead to permanent damage to the trust that customers have with your company. This will impact future orders and leave your brand with significant damage to its reputation.Wasted Resources

Overestimating customer demand for products leads to significant waste in time, money, and personnel. If turning over inventory fast enough becomes difficult, your business’s cash flow will be impacted. Having high levels of excess or obsolete inventory can lead to significant financial losses. To mitigate the high costs of failure, businesses now more than ever need to trust the numbers and adopt a sophisticated demand planning strategy that leverages data and market insights. Adopting automated demand planning strategies will lead to actionable forecasts.Aspects of Demand Planning

Understanding the work required within each element of demand planning will allow you to create the most accurate, up-to-date forecasts that will better inform your Sales and Operations Planning (S&OP).1. Product Portfolio Management

Many times, past sales performance can be used to forecast future sales performance. It is important to regularly upkeep and cleanse product data. Relevant data might include inventory, stockouts as they occur, seasonality, sales, and consumer demand through peaks and troughs. The difficulty here usually is the number of systems keeping these data sets as isolated transactions.2. Statistical forecast

Forecasts need a reference point, historical data in sales, inventory, and demand. Basically, what was actualized in the past can be a good indication of future sales. But not all data is useful, old data is typically not as useful as more current data as it might not correlate with future demand. The same bad situation happens when you do not use enough data to create a forecast. The right amount is typically trailing 24 months of most recent data.

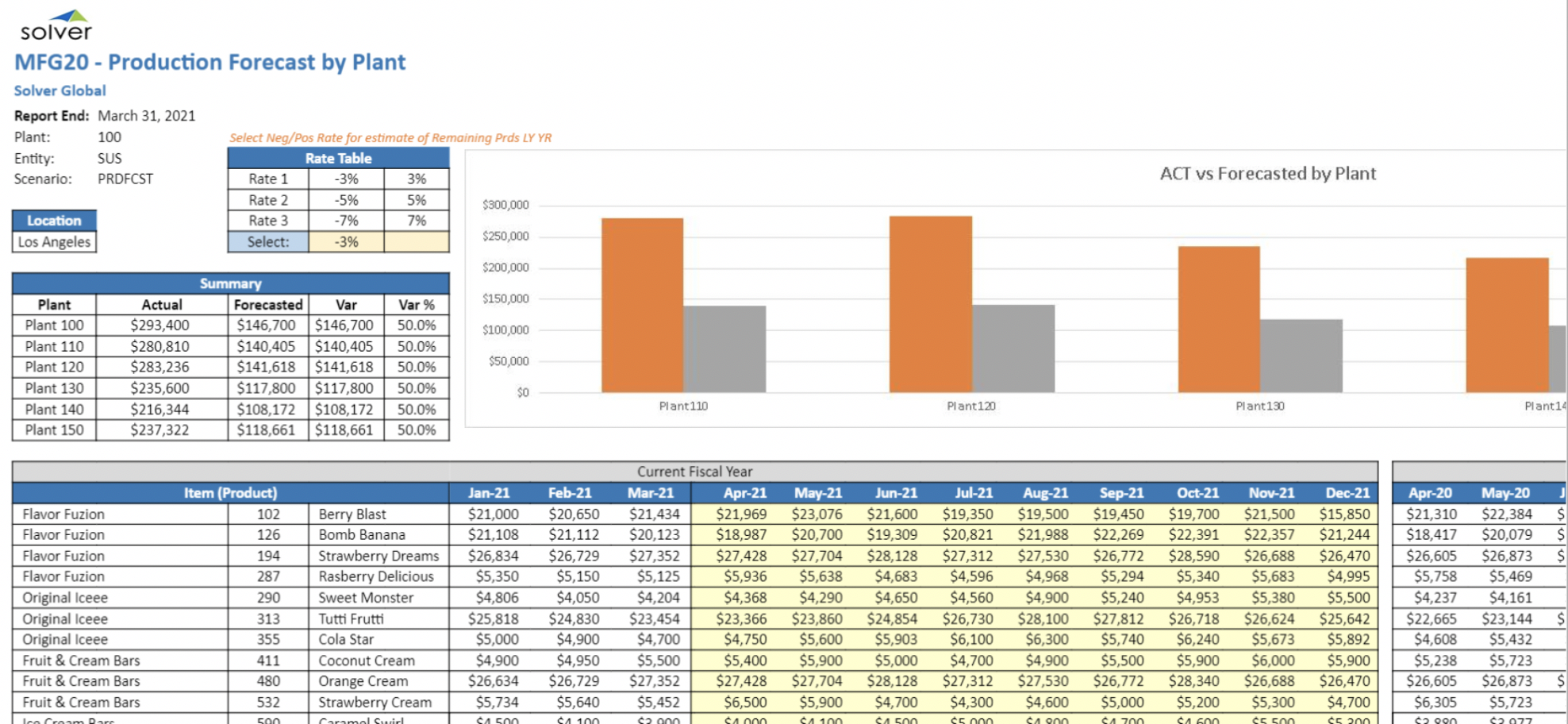

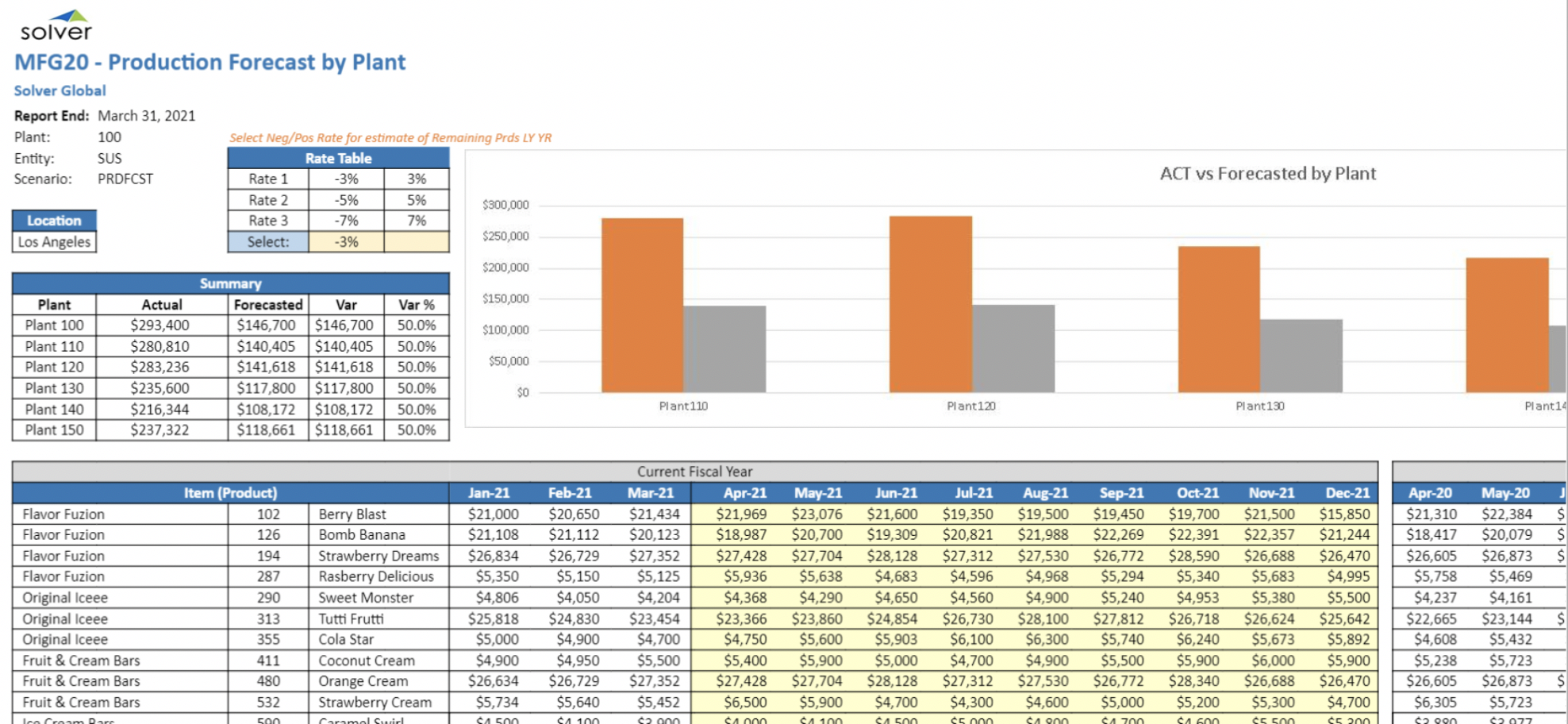

Example of an Automated Statistical Forecast

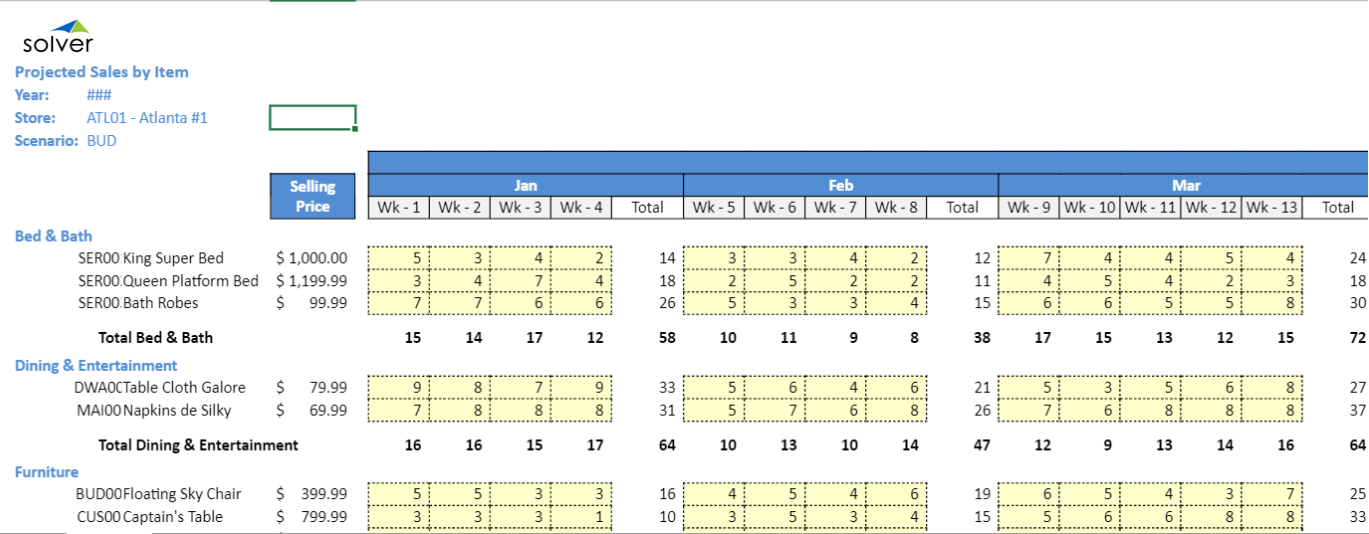

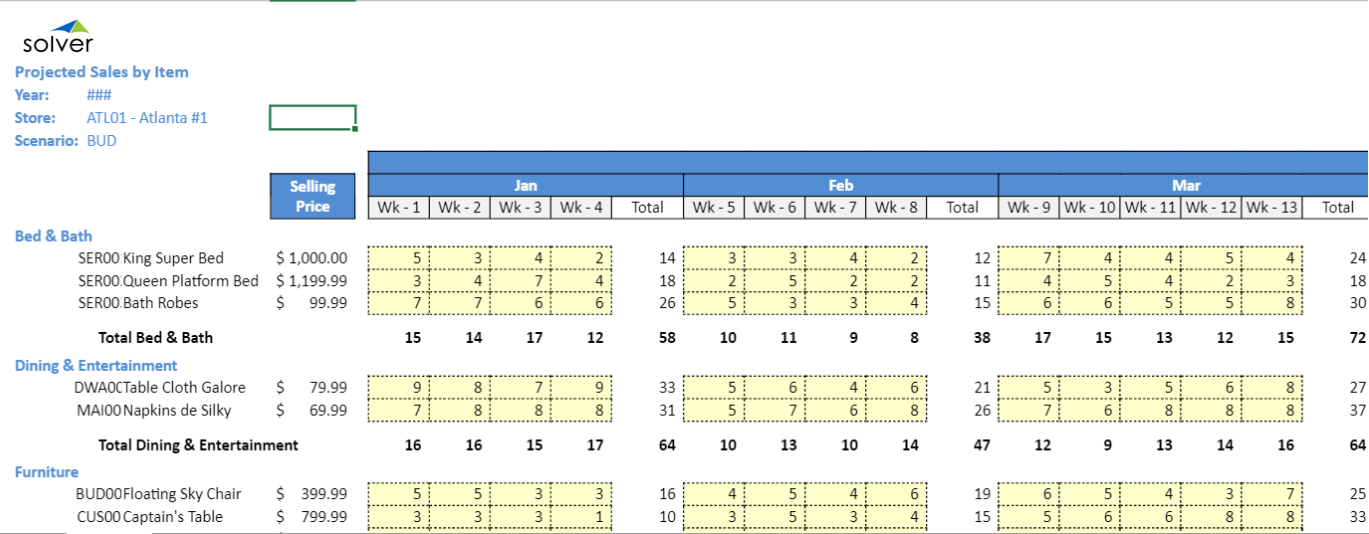

Example of Demand Planning of Weekly Sales by Item

3. Internal Trends

Internal trends relate to staffing issues at a level in the supply chain, seasonal demand due to product type, frozen capital, slow turnover, stockouts and general unpredictable sales volatility. Internal trends affect even the best-steered businesses which make it imperative to factor these causal influences into the forecast.4. External trends

External trends are another form of causal influence, but less predictable and usually harder to build into the demand planning forecast. External trends usually force a business to reforecast whereas internal trends are less likely to lead to a new forecast. Businesses that do reforecast and act on changing external trends like an economic recession or changing political climate are best positioned to succeed. COVID-19 has disrupted the majority of supply chains around the world in unprecedented scale. Amazon is probably one of the most recognizable organizations that have put tremendous effort into shifting its supply chain to prioritize the shipping of essential items. In light of COVID19, Amazon quickly refocused shipping priorities and product fulfillment to consumer essential goods. They have been quick to scale, pulling personnel and distribution resources from nonessential consumer goods and hiring 175k new workers in two months. Demand planners must be quick to identify factors that can impact demand such as natural disasters, news events, and internal and external unanticipated issues. To do so, an organization needs to be armed with a central repository of all its information to generate an accurate forecast and adapt to changing market conditions to meet customer demand.5. Events and promotions

A time-bound product promotion might lead to more sales in that time interval at a lesser margin. Holidays like Black Friday and Christmas can generate more sales in those few days than a whole month. Once a forecast is set, there needs to be a consensus on the actionable plan that comes out of the forecast. Part of this actionable plan is using events and promotions to hit sales and inventory targets. You want the right balance of inventory turnover, sales, while reducing COGS, and reducing waste of resources. Promos and external sales initiatives can help you get there.The Future of Demand Planning

Demand planning is becoming increasingly digital with advances in technology and machine learning. Demand planning software is being developed to better position businesses to adapt and update forecasts in real-time. An increasing number of businesses are now using CPM tools integrated with their ERP system to create multi-version forecasts that are constantly updated and refined to estimate future sales. A successful demand planning action will lead to countless benefits including:- Lower inventory costs

- Decrease in stockouts

- Waste reduction (obsolete inventory)

- Increase in on-time, in-full deliveries

- Decrease in expedited shipping costs

- Better pricing negotiation with suppliers

Contact Solver to Learn More about Demand Planning Software

Solver offers a flexible planning solution where powerful input forms are designed in Excel and deployed in the cloud. Solver can fit any business needs from a manufacturing company trying to forecast sales by month to a retail business looking to forecast SKU based on historical data. Solver’s cloud CPM solution is fully customizable to fit your demand planning needs. Contact our team today or request a demo for more information about our corporate performance management tool .

May 28, 2020

Global Headquarters

Solver Suite

Core Subscription

Company and Resources

© Copyright 2024, Solver All rights reserved.LegalPrivacy

QuickStart and Template Marketplace Overview (2 min) |QuickStart and Template Marketplace Setup (10 min)

Global Headquarters

Solver Suite

Core Subscription

Company and Resources

© Copyright 2024, Solver All rights reserved.LegalPrivacy

QuickStart and Template Marketplace Overview (2 min) |QuickStart and Template Marketplace Setup (10 min)

Global Headquarters

Solver Suite

Core Subscription

Company and Resources

© Copyright 2024, Solver All rights reserved.LegalPrivacy

QuickStart and Template Marketplace Overview (2 min) |QuickStart and Template Marketplace Setup (10 min)

Global Headquarters

Solver Suite

Core Subscription

Company and Resources

© Copyright 2024, Solver All rights reserved.LegalPrivacy

QuickStart and Template Marketplace Overview (2 min) |QuickStart and Template Marketplace Setup (10 min)